In many industrial processes that involve adhesive products, a special type of film is often used to prevent unwanted sticking. This film plays a key role in keeping adhesive materials in good condition until they are ready for use. One common type of this film is BOPP anti-adhesive release film, but many people still don’t fully understand what it is. This article will answer common questions about it, focusing on clear and practical information.

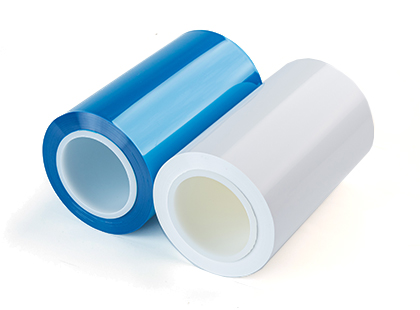

BOPP anti-adhesive release film is a specialized film made from BOPP (Biaxially Oriented Polypropylene) as its base material. The "anti-adhesive" feature comes from a special coating applied to its surface. This coating creates a low-tack surface, meaning adhesive materials can be placed on it without sticking permanently. When needed, the adhesive material can be easily peeled off the film without leaving residue or damaging either the adhesive or the film itself. It’s different from regular BOPP films because the anti-adhesive coating is designed specifically for compatibility with adhesive products.|

Good Temperature Resistance: Thanks to the BOPP base material, this film can handle a certain range of temperatures. It doesn’t easily deform or lose its anti-adhesive properties when exposed to moderate heat or cold, which makes it suitable for different production environments.

Smooth and Uniform Surface: The film has a flat, even surface, which ensures that the adhesive material placed on it adheres consistently (but not permanently) across the entire area. This helps maintain the quality of the adhesive product during storage or transportation.

Stable Peeling Performance: When peeling the adhesive material off the film, the force required stays relatively consistent. There’s no sudden "stickiness spike" that would make peeling difficult, and it doesn’t peel off too easily, which could lead to accidental separation.

The effectiveness of this film depends on several key factors related to its production and use:

Base Material Quality: The BOPP material itself needs to be uniform in thickness. If the base is uneven, the anti-adhesive coating can’t be applied consistently, leading to spots where adhesive might stick too strongly.

Coating Application Process: The special anti-adhesive coating must be applied in a thin, even layer. Too thick a coating may reduce peeling smoothness, while too thin a layer can cause the anti-adhesive effect to fade quickly.

Storage Conditions: When storing the film, it should be kept in a dry, cool environment. High humidity can make the film absorb moisture, weakening its structure, and extreme heat can damage the coating’s anti-adhesive properties.

BOPP anti-adhesive release film is a practical solution for industries working with adhesive products. Its base material and special coating work together to provide anti-adhesive properties, good durability, and consistent performance. Understanding what it is, its key traits, and what affects its performance can help businesses choose and use it more effectively.

If you want to learn more about release films that fit different industrial applications, you can visit our product page. There, you’ll find detailed information about various release film options designed to meet different practical requirements.