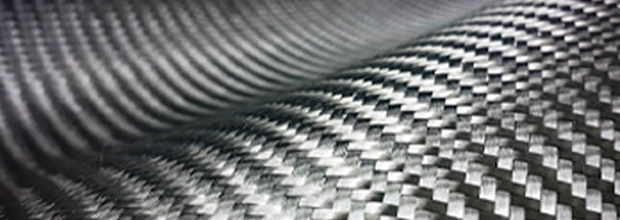

As advanced composite materials continue to replace traditional metals in aerospace, marine, UAV, and sporting goods industries, auxiliary materials play a critical role in ensuring production quality and process efficiency. Among them, PET Release Film is an essential consumable widely used in prepreg processing, vacuum bagging, and composite curing applications.

This article explains what PET release film is, how it works in prepreg manufacturing, typical release force ranges, and its applications in carbon fiber parts such as boat paddles, drone propellers, and composite blades.

PET Release Film is a polyester-based (PET) film coated with a specially formulated release layer that provides controlled and consistent separation between composite materials and tooling or auxiliary layers.

In composite manufacturing, PET release film prevents resin systems—such as epoxy, phenolic, or thermoplastic resins—from bonding to vacuum bags, breather fabrics, or mold surfaces during curing.

Release force is a critical parameter when selecting PET release film. It is usually measured in grams per inch (g/in) and varies depending on coating formulation.

|

Release Type |

Typical Release Force |

Recommended Applications |

|

Light Release |

5–30 g/in |

Fragile prepregs, automated processing |

|

Medium Release |

30–100 g/in |

Standard carbon fiber prepreg systems |

|

Heavy Release |

>100 g/in |

High-tack adhesives, special bonding |

PET release film plays multiple roles throughout the composite production process:

During prepreg production and storage, PET release film separates resin-impregnated fiber layers, preventing blocking and enabling easy handling.

In vacuum bag or autoclave curing, PET release film acts as a release interface between the laminate and auxiliary materials such as bleeder and breather fabrics.

For visible composite surfaces—such as drone blades or marine paddles—PET release film helps achieve a smooth and uniform finish, reducing post-processing.

In marine applications, PET release film ensures consistent resin distribution, prevents resin leakage into vacuum layers, and improves demolding efficiency for long or curved components.

High-performance UAV propellers require precise fiber alignment and surface quality. PET release film supports stable curing processes and helps achieve repeatable mechanical properties.

From sports equipment to industrial composite blades, PET release film improves manufacturing yield while maintaining surface integrity and dimensional accuracy.

Beyond composite manufacturing, PET release film is also widely used in:

This versatility makes PET release film a critical functional material across multiple industries.

Sanlin New Materials supplies PET release films with:

Our products are designed to support demanding composite manufacturing environments.